Custom Plastic Tubing

Made from molten polymer plastic fed through a customized die, custom plastic tubing is used in many industries, including medical, food and beverage, automotive, and construction. While standard plastic tubing comes in pre-made dimensions and shapes, custom tubing provides greater utility. By customizing the material, size, and profile, plastic tubes become more efficient, cost-effective, and versatile.

Freelin-Wade is the industry’s leading supplier of custom plastic tubing. We offer 28 standard colors and can custom match or create any color your project requires using any Pantone® color or a color swatch.

Freelin-Wade is your custom plastic tubing expert. Contact us today to discuss your custom requirements.

Literature and Additional Information

Customized Plastic Tubing from Freelin-Wade

Freelin-Wade specializes in custom plastic tubing to make projects more accessible and cost-effective for our customers. We offer more than 4,000 standard tubing, hose, and accessories with endless customizations to meet your application needs, all ready to ship within 24 hours.Learn more about our customization techniques from our informational video.

Custom Flexible Plastic Tubing Options

Freelin-Wade proudly offers superior services for custom tubing.Bonded Plastic Tubing

With our in-house specialty bonding technology, Freelin-Wade can combine two or more tubes of any size and color to simplify any future troubleshooting, replacement, or line tracing. Our bonding process allows tubes to be easily separated, leaving no residue behind. Color-coded plastic tubing makes organization a breeze!Coextruded Plastic Tubing

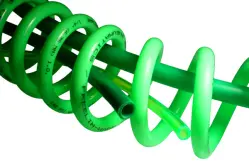

With our coextrusion capabilities, customers are no longer limited to the properties of a single tube. We can combine multiple materials by pressing them through the same die, creating a single plastic tubing with all the properties your project requires. If you need the flexibility of polyurethane and the chemical resistance of nylon, coextrusion is your answer.Coiled Plastic Tubing

Coiling effectively organizes flexible plastic tubing while still getting the most out of the tube’s working length. By customizing your tubing diameter, you are also customizing the retractability of the coil and the length at which it can be stretched and used comfortably. You can add coiling to any nylon or polyurethane standard or custom tubing.Jacketed Plastic Tubing

Jacketing offers an additional method to organize your tubing with a clean, user-friendly experience. We provide expandable webbing and spiral wrapping and can bundle assorted sizes, materials, and colors with PVC-jacketed extruded bundles. Freelin-Wade has developed a superior process for jacketing long lengths and can bundle various wires and tubes together.Plastic Tubing Shapes & Profiles

While most plastic tubing is round, we can provide custom tubing in virtually any shape. Our expert team will work with you to ensure that the profile you receive matches your exact requirements.Additional Tubing Options

Alternative tubing services from Freelin-Wade include:- Prototype Customization

- Tubing Bundling

- Color Customization

- Custom Tube Cutting

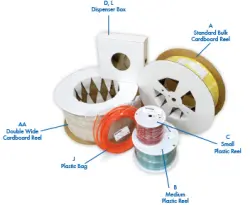

- Packaging & Labeling

- Custom Printing

- Custom Dimensions & Sizing

Contact Us for Custom Flexible Plastic Tubing

Freelin-Wade is your trusted supplier of custom plastic tubing. Our experts are prepared to assist you with all your tubing needs.

Contact us today to learn how we can create tubing that’s right for you.